PC-Dmis Solutions

Automation, Tools & Data Solutions

PC-Dmis is highly extensible - the inner workings are accessible for automation and customisation either through code or built in tools.

Automettech are experts in this field and our solutions are used in industries from aerospace to F1, to streamline and integrate PC-Dmis with wider manufacturing and quality systems.

Systems

Integration with robotics or automated systems

Automation & Macros

-

Automate repetitive tasks

-

Make bulk changes to programs

An aerospace customer had a requirement to create several constructed & generic features, and associated dimensions for each hole in a drill jig (around 10 additional commands per hole) with 200+ holes in a typical jig.

This was a common requirement on many of their jobs, and took up a lot of time.

We were able to create a script which would automatically generate the required commands and saved them days of work over the course of the project

A large machine shop had a seemingly simple requirement to update and standardise probe builds and names throughout their programs. The problem was they had upwards of 400 programs. We automated the task and all 400+ programs were updated in under an hour.

An aerospace engine manufacturer identified an error in some of their programs where an incorrect setting was leading to a miscalculation of a bonus tolerance. It would have taken an estimated 300 man hours to review and fix all their programs.

A simple script accomplished the job in under eight - this including writing the script.

PC-Dmis Tools

We've years of experience with PC-Dmis, and can quickly evaluate which (if any) of the in-built tools will fit your requirements - we'll take into consideration how complex, robust and fit-for-purpose each possible solution might be and explain your options to you.

-

Report Templates - Like the different reports which ship with PC-Dmis these can work on any program. Report measurement results exactly as you want, add cover sheets, sign-off sheets, or break reports into sections for different end users.

-

Forms / Hyper Reports - Make interactive programs. Whether it's collecting relevant data from the operator (Tool or Cavity Number, Machine ID, Customer etc) to add to the report or output to a statistics package, or controlling the input into parametric programs which can 'adapt' to measure a range of similar parts, Forms and Hyper Reports can add power to your programs.

-

Custom Reports - Custom reports aren't bound by program execution order, dimensions can be put anywhere within the report you choose, and linked to specific 'CAD' views - great when you need something 'just so' to really convey what's going on with a part to a less technical audience.

Bespoke Report Template

Custom Data Entry Form

Data Solutions

-

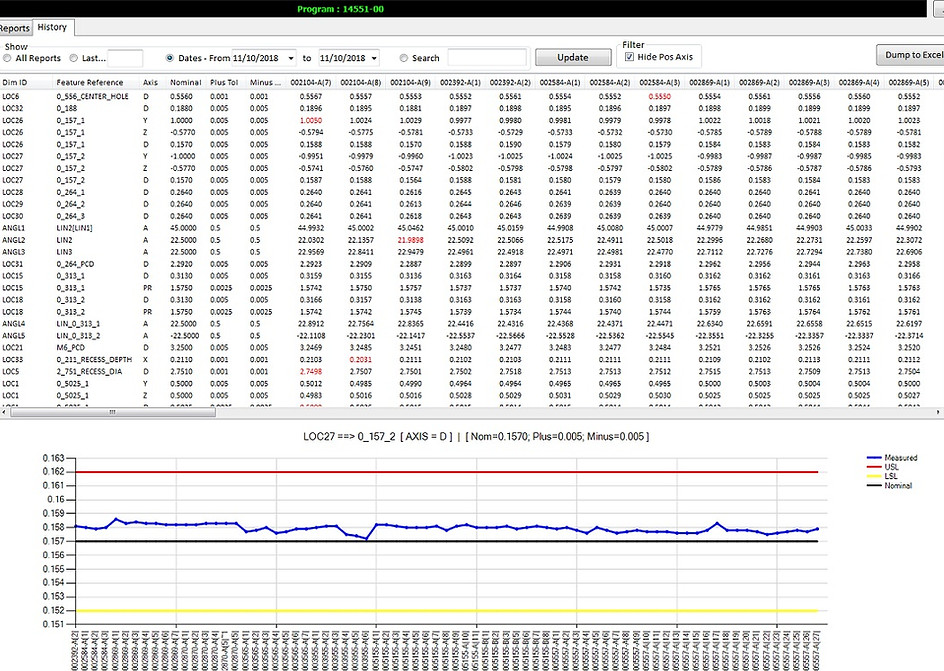

Get measurement data out of PC-Dmis in the exact format you want: .xls or .xlsx (Excel), .txt or .csv (or any other text based format) or .XML without the need for macros or scripts - ready for import into your analysis and SPC packages.

-

Auto-fill Excel inspection report templates to keep PC-Dmis reporting in line with existing document layouts.

-

Filter report data by In / Out Tol, Feature or Dimension Type, Critical features or any other way you choose.

-

Automate data transfer between PC-Dmis and your third party SPC software.

-

Systems to ensure all trace data is collected in a uniform and consistent fashion - make sure your CMM inspection adheres to your company's quality systems.

RepDmis Report Database

Operator Interfaces

-

Allow machine setters and operators to safely run CMM programs with little or no training

-

Select and launch part programs with the scan of a bar code

-

Create a queue or playlist of programs to run on your CMM, for longer periods of unattended CMM operation

RunDmis Operator Interface

Program Management

-

Distribute programs across networks to multiple CMMs

-

Manage revision changes

-

Archive part program data

-

Prevent unauthorised or accidental modifications to approved programs